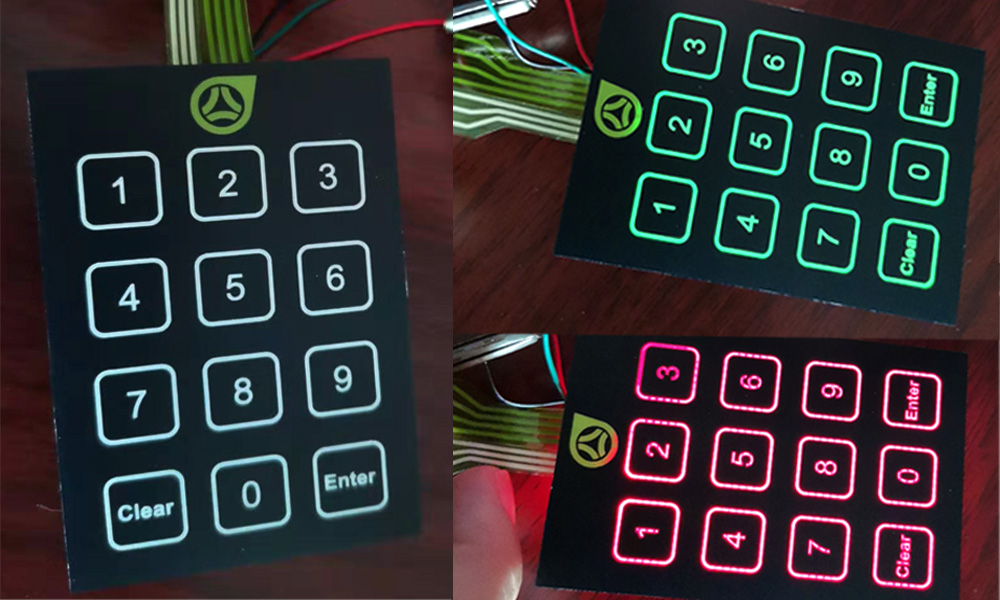

How switch backlighting can upgrade lighting appeal

Wiki Article

The Manufacturing Refine Behind High-Quality Switch Backlighting Solutions

The production process behind top quality switch backlighting solutions entails numerous critical points. It begins with a collaborative layout stage that merges engineering and design understandings. Advanced methods are used for prototyping, complied with by rigorous screening and improvement. As production scales up, an emphasis on quality materials and automated setting up ends up being vital. Quality control actions are incorporated throughout, making sure efficiency and longevity. The details of each phase disclose deeper understandings into what truly drives excellence in this area.Recognizing the Style Considerations for Switch Backlighting

When creating switch backlighting, it is imperative to ponder various variables that influence both capability and aesthetic appeals. The option of lighting type, such as LED or optical fiber, considerably effects visibility and energy performance. Additionally, the illumination level should be adjusted to guarantee suitable readability in different illumination problems without causing glare. The shade temperature level also plays a fundamental function; warmer tones can produce a welcoming ambience, while cooler tones might suggest an extra contemporary appearance.Developers need to additionally think about the placement and size of the backlighting to achieve also circulation and prevent hotspots. The combination of dimming functions can boost individual experience, allowing for customization based on specific preferences. The general layout must harmonize with the tool's style, making sure that backlighting complements instead than detracts from the total looks. switch backlighting. Each of these considerations is important for developing a visually attractive and reliable switch backlighting remedy

Choosing the Right Products for Optimum Performance

Selecting the right products is essential for ensuring ideal performance in switch backlighting options. The selection process entails considering aspects such as durability, light transmission, and thermal residential or commercial properties. The usage of top quality polymers can enhance light diffusion while preserving structural honesty under differing temperature levels. Additionally, materials like acrylic and polycarbonate are prominent as a result of their outstanding optical clearness and resistance to yellowing gradually.In addition, the choice of LED components plays a significant function; they ought to be suitable with the selected materials to optimize illumination and power efficiency. Conductive products must be picked carefully to assure dependable electrical links without endangering the general style. Environmental considerations, such as recyclability and sustainability, are increasingly affecting material selection in modern-day production. By prioritizing these facets, suppliers can attain high-performance switch backlighting solutions that fulfill consumer expectations.

The Modern Technology Behind Efficient Lighting Solutions

Innovations in innovation have substantially transformed the landscape of efficient illumination services in switch backlighting. The combination of LED (Light Emitting Diode) innovation has actually become a crucial advancement, supplying exceptional power performance and durability contrasted to conventional lights methods. LEDs eat significantly much less power while delivering high luminance, making them an optimal selection for backlighting applications.Additionally, the growth of smart lights systems has actually enabled boosted control over brightness and color temperature level, allowing for greater modification and improved individual experience. These systems commonly make use of sensors and programmable user interfaces, adjusting to user preferences and environmental conditions.

Furthermore, improvements in optical layout, such as diffusers and reflectors, have enhanced light distribution, guaranteeing uniform illumination across different surfaces. This mix of LED innovation, clever systems, and ingenious optical aspects has resulted in the production of backlighting solutions that are not just efficient yet additionally cosmetically pleasing, boosting the overall functionality of tools.

The Production Refine: From Idea to Development

While the journey from concept to production in button backlighting production includes several meticulous phases, it starts with the style phase, where designers and designers work together to establish cutting-edge concepts that fulfill market needs. This phase emphasizes capability and aesthetics, ensuring that the end product is not only reliable but additionally aesthetically appealing.As soon as the style is completed, models are created using advanced production methods, permitting real-world screening and refinement. Responses from these examinations leads to essential changes, making certain that the backlighting services perform successfully under various problems.

Following effective prototyping, the manufacturing phase starts. This involves scaling up the production procedure, which consists of sourcing premium products, executing automated production line, and integrating accuracy technology to preserve uniformity. Each step is carried out with treatment, making sure that the site link switch backlighting options await distribution to satisfy customer assumptions and industry requirements.

Guaranteeing Top Quality Control in Backlighting Production

A robust quality assurance system is crucial in the production of switch backlighting options to assure that every unit satisfies strenuous standards. This system usually includes numerous phases, starting with the selection of high-grade products - switch backlighting. Each part goes through rigorous testing to verify it lines up with efficiency requirementsThroughout manufacturing, drivers perform real-time inspections to identify defects early, reducing waste and confirming uniformity. Advanced modern technologies, such as automated optical inspection, are employed to monitor soldering quality and light harmony, better boosting reliability.

Often Asked Questions

Just How Do Various Colors Affect Switch Backlighting Presence?

Various colors greatly influence switch backlighting exposure; brighter colors boost clearness and readability, while dimmer shades might obscure details. The selection of color affects customer experience, affecting functionality in varied lighting settings and applications.What Are Typical Applications for Switch Backlighting Solutions?

Common applications for button backlighting options include automotive control panels, computer keyboards, pc gaming controllers, home appliances, and commercial devices. These remedies improve use and looks, offering clear presence and improving individual experience in numerous environments and lights conditions.

Can Switch Backlighting Be Customized for Certain Brand Names?

Yes, Switch backlighting can be customized for certain brand names (switch backlighting). Producers usually tailor styles, shades, and brightness levels to straighten with brand name identities, making sure that the backlighting enhances the overall aesthetic appeals and capability of the productsWhat Regulations Govern Switch Backlighting Manufacturing?

Rules regulating switch backlighting production consist of safety and security standards, electromagnetic compatibility demands, and environmental standards. Conformity with these laws ensures items are risk-free, reliable, and eco-friendly, eventually promoting consumer blog depend on and market feasibility in the sector.Just How Do Ecological Factors Influence Backlighting Performance?

Environmental factors, such as temperature and humidity, considerably affect backlighting efficiency. Severe problems can impact light output, shade precision, and element durability, eventually impacting the reliability and effectiveness of the brightened buttons in different applications.The manufacturing process behind premium switch backlighting services involves numerous essential phases. Selecting the best materials is essential for assuring optimal performance in switch backlighting solutions. Innovations in modern technology have greatly changed the landscape of effective lighting remedies in switch backlighting. A durable high quality control system is vital in the production of button backlighting options to guarantee that every device satisfies rigorous requirements. Common applications for button backlighting services consist of automobile dashboards, computer system keyboards, pc gaming controllers, home appliances, and commercial equipment.

Report this wiki page